CASE STUDY:

CARBON

FIBER

MACHINE

TOOLING

Toroidal graphene enhanced carbon fiber composite was first developed for machine tool holding. Machining is a very hot, sometimes chemically active environment, where the pressure and rotational speeds are extreme. Cutting forces are causing flexural, torsional and tensile stresses in the tool, causing vibration tool deflection and lack of stability in holders.

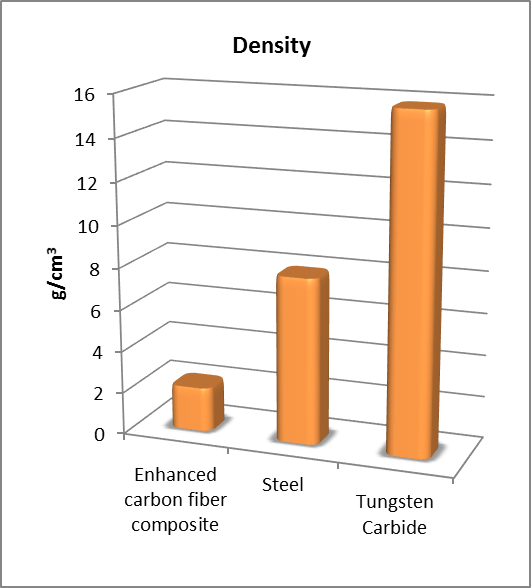

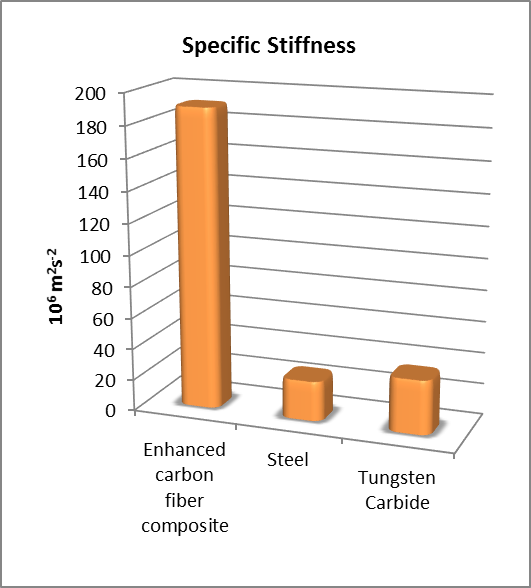

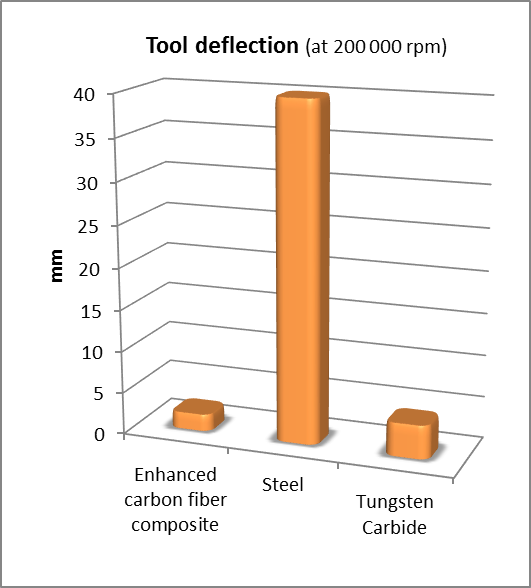

In the aggressive environment of machining, where lightweight is normally not a factor, Toroidal graphene enhanced carbon fiber composite is out-performing steel and surpassing the performance of tungsten carbide in deflection properties.

The obvious application for a material with this level of deflection and modulus properties is aircraft wings, but there is also a good probability that Toroidal grpahene enhanced carbon fiber composite could be used for automotive and aircraft parts that until now have been reserved for other materials than carbon fiber composites.

OUT-PERFORMING STEEL.

SURPASSING TUNGSTEN CARBIDE

IN DEFLECTION PROPERTIES.

ADDRESSING PROBLEMS OF FORCES

INVOLVED IN MACHINING.

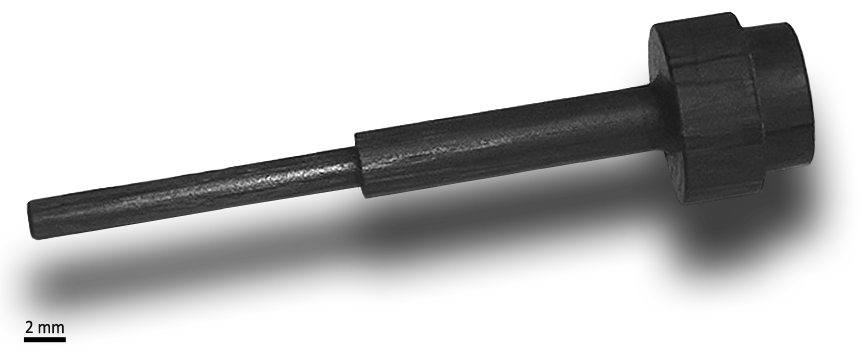

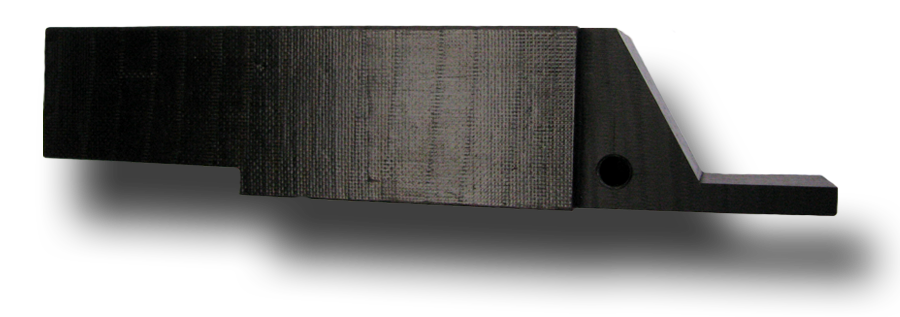

Toroidal graphene enhanced carbon fiber composite vibration dampening tool holders and quills are addressing the problems of the forces involved in machining and is evidence of the crucial importance of complete tool solutions for the overall production economy. Despite the fact that machine tools represent a small part of the total production, the right tool solution result in cost savings of up to 20% of the total cost. Reduced environmental impact and lower total cost is driving demand for highly effective tool solutions.

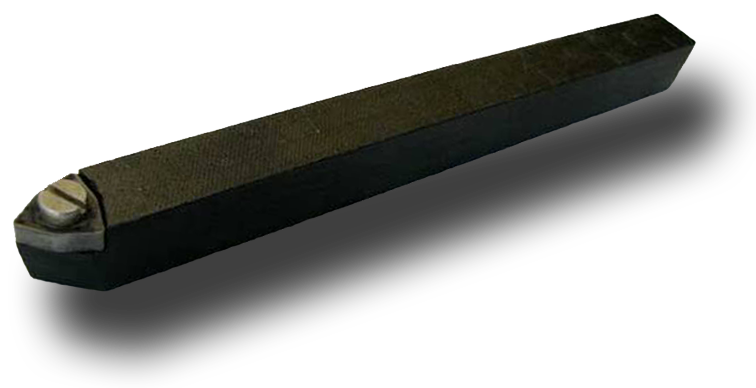

A cutting tool is made up of a cutting edge and a holder. During machining, the cutting edge wears out in matter of minutes as the service life is considered to be over. Cutting edge service life is defined as the effective production time during which the cutting edge can be used in machining of components and pass specified tolerances. It is of paramount importance that it’s possible to predict the theoretical cutting edge service life with great confidence, as most processing is done in machines destitute of monitoring or even supervision. Extended processing past the service life of the cutting edge invariably leads to insert failure or breakdown. Selecting the appropriate cutting edge is critical in obtaining maximum productivity in processing.

It is imperative to get everything right in a very hot, chemically active environment where the pressure and rotational speeds are extreme. The cutting forces are causing flexural, torsional and tensile stresses in the tool, causing vibration, tool deflection and lack of stability in holders and clamping. These are the contributing factors that shorten the service life of the cutting edges. So far, the best available technology has been to use steel for holders of cutting tools, or carbide for applications where stiffness is paramount. The high tensile modulus of carbide reduces tool deflection, but its high weight means that the eigenfrequency rate is lowered, which may result in additional vibration problems. To avoid excessive wear of the cutting edges resulting in problems such as poor surface finish; insufficient accuracy; increased wear of machine tools; and high noise level, the cutting forces must be restrained, leading to inefficiency and costly productivity losses.

LET'S GET

TOGETHER.

If you believe that we may have a technology that could be of benefit to your company ...

or if you just want to chat …