CASE STUDY:

BRONZE

STEEL INDUSTRY

BACKGROUND

Steel is the world's most important engineering material due to high strength relative to weight and price. Steel is produced in many forms - from thin sheets to coarse supporting bridge beams.

Most of the steel manufacturing consists of products to be processed and further refined. This is usually done by hot rolling to form various products such as plates, strips, rods, profiles, wires and pipes. Sometimes, additional cold rolling is applied for example in the manufacturing of thin sheet metal.

Rolling mills can consist of thousands of rolls and are constantly running around the clock, year-round. In order to maintain tolerances and surface finish, maintenance of the rolls is an absolute necessity, and the rolls are therefore grinded regularly to prevent that the steel is processed with defective rolls, which would have very negative consequences.

In the event of processing with a defective roll, the rolled steel can, at best, simply be processed again, but to lift steel in and out of the mill takes time and involves an extra cost as the process time will be longer. In the more negative case steel rolled with full force. This can destroy both the rolling mill roll packages and peripherals. This means that a total of twenty different rollers must be replaced. A time-consuming work that takes more than one shift to perform. This leads to large production time losses as well as increased total production expenses as downtime costs are around $10,000 per hour. Of course, the security aspect is another major concern, as a defective roll in the worst case can be the cause of an accident.

PROBLEM

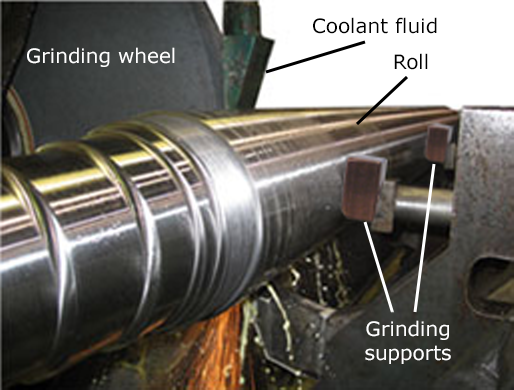

The grinding of rolls is performed with a rotating grinding wheel which is moved horizontally back and forth along the roll.

The grinding process generates heating of the roll to extreme temperatures and the roll must be cooled to avoid overheating. The coolant fluid also removes the dust generated during the grinding.

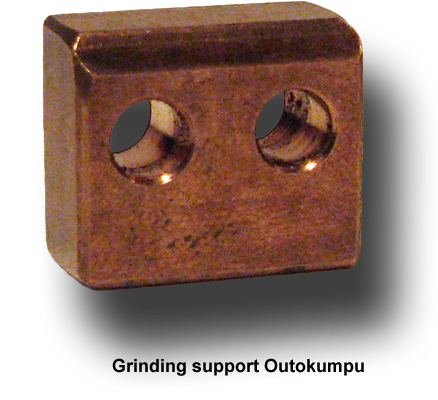

To ensure that the rolls, which can be very large and heavy, do not bend from the abrasive forces and their own weight grinding supports are used. Grinding supports are usually made of bronze because it is a softer material than steel and can’t destroy the steel rolls during grinding. The regular bronze grinding supports wear out quickly by the steel rolls and by the residual dust generated in the grinding process. Therefore, the grinding supports are exchanged at regular intervals.

The steel manufacturing plant Outokumpu in Avesta, Sweden wear out 8 grinding supports per machine per week. Outokumpu has two machines in the Avesta. Another example is the German steel manufacturer Thyssen with several plants, at the Krefeld plant at full production wear out 18 grinding supports every three days and at the Benrath plant 12 grinding supports every three days. The difference in how frequently the grinding supports are exchanged in the different plants depends on the geometry of the grinding supports.

SOLUTION

Grinding supports made of bronze modified by Toroidal graphene last considerably longer than conventional unmodified bronze grinding supports.

The improved functionality, thanks to our far more durable Toroidal graphene/bronze composite material represents great savings especially in the process-time, where downtime is reduced to less than 20%.

500%

IMPROVEMENT

IN

ABRASIVE

WEAR

RESISTANCE

Grinding supports made of bronze modified by Toroidal graphene have been tested both by Outokumpu in Avesta, Sweden and by Thyssen at their plant in Krefeld, Germany.

We produced grinding support prototypes both for Outokumpu and Thyssen for testing purposes. The initial tests have showed very good results, with the grinding supports made of bronze modified by Toroidal graphene lasting at least five times as long as the conventional grinding supports with the same lubrication (coolant fluid) and in the same environment.

FEATURES

&

BENEFITS

Bronze modified by Toroidal graphene offers high strength and excellent corrosion resistance in combination with fatigue strength, galling resistance, magnetic transparency, resiliency and high hardness.

Innovative design

Bronze modified by Toroidal graphene offers design flexibility. Because the nanostructured alloy is dispersion-hardenable, it can be produced in a wide range of strengths. Property combinations within this range can be tailored to the individual application requirements.

The uniquely tailored properties of Solerial Bronze make it the material of choice for a wide variety of products. Performance can be improved and service life extended using this alloy, leading to significant savings in processing, completion and production costs.

Machinability

Bronze modified by Toroidal graphene can be machined using conventional methods. Because of easy chip removal, machinability of bronze modified by Toroidal graphene is better than that of other high performance alloys. Since machinability rates are much higher, production is more efficient and manufacturing costs are reduced. The material can also be electrical discharge machined, photo-chemically etched, welded and brazed.

Corrosion Resistance

Bronze modified by Toroidal graphene has excellent corrosion resistance. In marine environments, its performance is unsurpassed. The low sea water corrosion rate makes bronze modified by Toroidal graphene an ideal material choice for subsea components. Additionally, bronze modified by Toroidal grpahene is not susceptible to sulfide or chloride stress corrosion cracking, resists carbon dioxide and is effectively immune to hydrogen embrittlement. In sour environments, it is used where exposure is intermittent.

Galling Resistance

Bronze modified by Toroidal graphene has superior galling resistance. This is one of the primary reasons that bronze modified by Toroidal graphene can be selected for equipment where the service conditions include high loading and relative motion between metal components. Bronze modified by Toroidal graphene resists galling to many other alloys and resists galling to other components made of Bronze modified by Toroidal graphene.

Cryogenic Behaviour

Bronze modified by Toroidal graphene can be used in liquefied gases and at sub-zero temperatures since strength, ductility and toughness are maintained in cryogenic conditions. Bronze modified by Toroidal graphene has no ductile to brittle transition temperature, as do many high strength steels.

Magnetic Properties

Bronze modified by Toroidal graphene is non-magnetic. Magnetic permeability is near unity meaning that the alloy is nearly perfectly transparent to slowly varying magnetic fields. Localized deformation or surface abrasion will not cause magnetic “hot spots” and the material will not become magnetized by machining.

LET'S GET

TOGETHER.

If you believe that we may have a technology that could be of benefit to your company ...

or if you just want to chat …